Motorcycle repair centers face challenges with traditional diagnostic methods due to motorcycles' intricate nature and complex electronics. AI tools, leveraging machine learning and computer vision, have emerged as a game-changer, automating initial checks, providing real-time insights, and reducing troubleshooting time. These tools significantly improve operational efficiency by analyzing vast data sets for accurate diagnostics, expediting service times, enhancing customer satisfaction, and creating a leaner work environment. Best practices involve integrating AI across all repair stages, training staff, and regularly updating models to maintain accuracy.

In the fast-paced world of motorcycle repair, efficient diagnostics are key to maintaining operational excellence. With increasing customer demand and complex bike designs, traditional methods struggle to keep up. This article explores how AI tools for enhancing motorcycle repair diagnostics can revolutionize the industry. We delve into understanding the unique challenges, examining the role of AI in streamlining processes, and providing practical insights on implementing these advanced solutions for repair centers.

- Understanding the Challenges of Motorcycle Repair Diagnostics

- The Role of AI Tools in Streamlining the Process

- Implementing AI: Benefits and Best Practices for Repair Centers

Understanding the Challenges of Motorcycle Repair Diagnostics

Motorcycle repair centers face unique challenges when it comes to diagnostic processes, largely due to the intricate nature of these vehicles and the wide array of potential issues they can encounter. Traditional diagnostic methods often rely heavily on experienced technicians who must manually inspect and test various components, a process that can be time-consuming and prone to human error. The complexity of modern motorcycles, with their advanced electronics and interconnected systems, adds another layer of difficulty to accurate and swift diagnostics.

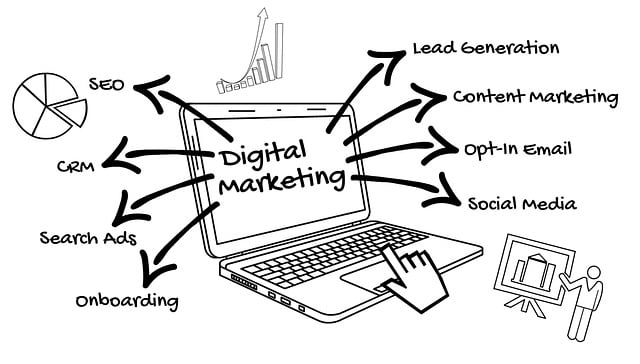

AI tools for enhancing motorcycle repair diagnostics have emerged as game-changers in this landscape. These tools leverage machine learning algorithms and computer vision to analyze vast amounts of data from sensors and diagnostic scans, enabling faster identification of issues. By automating initial checks and providing technicians with real-time insights, AI assists in reducing the time spent on troubleshooting, allowing mechanics to focus on more complex repairs. This not only improves operational efficiency but also ensures that customers receive quicker service.

The Role of AI Tools in Streamlining the Process

The integration of AI tools in motorcycle repair centers is transforming the way mechanics approach their work, significantly enhancing operational efficiency. These advanced tools can analyze vast data sets to provide accurate diagnostics, enabling faster and more effective repairs. By employing machine learning algorithms, AI systems can identify patterns and anomalies in engine performance, transmission issues, and other common problems, allowing technicians to pinpoint issues with greater precision.

Furthermore, AI tools streamline the process by automating routine tasks such as parts inventory management and ordering, reducing human error and minimizing downtime. This not only expedites service but also improves overall customer satisfaction, as repairs are completed more quickly and accurately. The ability of AI to continuously learn and adapt makes it an invaluable asset in motorcycle repair centers, contributing to a leaner, more productive work environment.

Implementing AI: Benefits and Best Practices for Repair Centers

Implementing AI, particularly AI tools for enhancing motorcycle repair diagnostics, can significantly boost operational efficiency in repair centers. These advanced tools can analyze vast amounts of data to pinpoint patterns and anomalies in engine performance, transmission issues, and other common problems, leading to faster and more accurate diagnostics. This not only reduces the time spent on troubleshooting but also ensures that repairs are done with precision, minimizing the risk of recurring issues.

Best practices for adoption include integrating AI into every stage of the repair process, from initial assessments using computer-aided diagnosis (CAD) systems to predictive maintenance models that anticipate when routine services or major repairs are needed. Training staff on these new technologies is crucial, ensuring they can leverage AI’s capabilities effectively. Regular updates and calibrations of AI models based on new data also help maintain accuracy over time.

AI tools have the potential to revolutionize motorcycle repair centers by significantly enhancing operational efficiency. By automating diagnostic processes, these tools can reduce time and labor costs while increasing accuracy. Implementation of AI technologies allows repair centers to stay competitive in a rapidly evolving market, ensuring faster turnaround times for customers and improved overall service quality. Embracing these advancements is a strategic move towards future-proofing the industry.